All Products

-

JonathasThe coupler they suggested are quite suitable to replace old ones. Price is reasonable, and looking forward to receive the thhem.

JonathasThe coupler they suggested are quite suitable to replace old ones. Price is reasonable, and looking forward to receive the thhem. -

JoseThe DF8B spare parts I got are all correct. Lead time is fast, and anytime I have problems, Sunny are always here to help me. Thanks her a lot,and looking forward to our future cooperation again.

JoseThe DF8B spare parts I got are all correct. Lead time is fast, and anytime I have problems, Sunny are always here to help me. Thanks her a lot,and looking forward to our future cooperation again.

Contact Person :

Wei Dong

Phone Number :

+86-13368201198

whatsapp :

+8613368201198

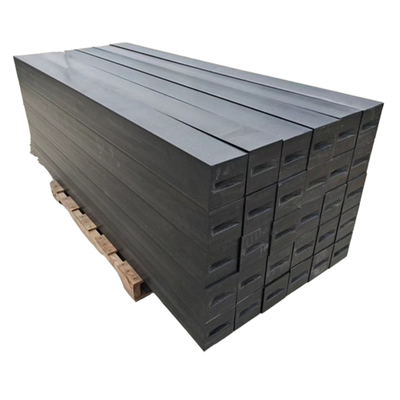

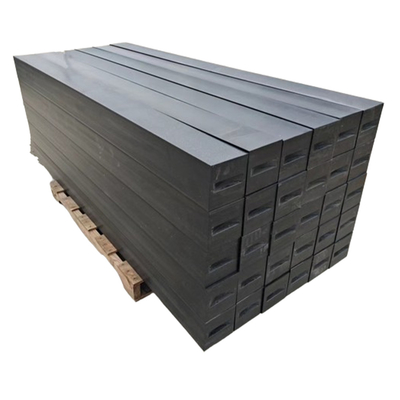

Best Cost Performance High Strength Anti-Aging Railway Composite Rubber Sleeper

Contact me for free samples and coupons.

whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Product Name | Composite Sleepers | Material | PE |

|---|---|---|---|

| Color | Customized | Quality Control | 100% Inspection |

| Size | 100*100*1300mm | ||

| Highlight | High Strength Railway Composite Rubber Sleeper,Anti-Aging Railway Composite Rubber Sleeper |

||

Product Description

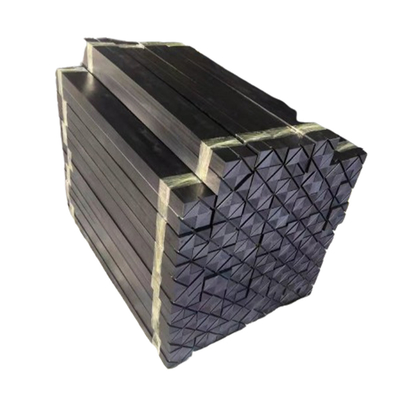

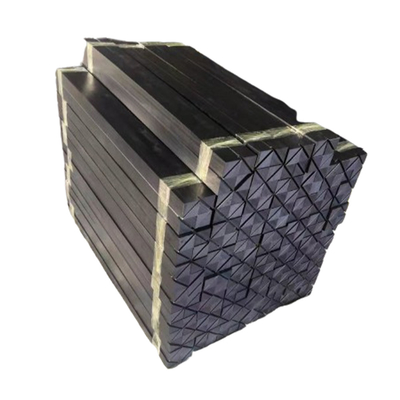

| Normal sleepers | Turnout sleepers (Normal) | Turnout sleepers (Standard) | Bridge sleepers | |

| Width | 100mm | 150mm | 200mm | 300mm |

| Thickness | 100mm | 150mm | 200mm | 300 mm |

| Length | 1000-1300mm | 1000-1300mm | 1000-1300mm | 1000-1300mm |

Rail composite sleepers, as a modern alternative to traditional wooden or concrete sleepers, offer several significant benefits:

1. Durability and Longevity

* Corrosion Resistance: Composite materials are highly resistant to water, corrosion, and UV exposure, making them ideal for harsh environments.

* Aging Resistance: The structural stability of composite sleepers ensures minimal deformation or degradation over time, with a lifespan often exceeding that of traditional sleepers.

2. Environmental Benefits

* Reduced Timber Usage: Compared to wooden sleepers, composite sleepers help conserve forest resources.

* Recyclability: Many composite sleepers are made from recycled plastics and fiberglass, and they can be recycled at the end of their service life, supporting sustainability.

* Lower Carbon Emissions: Manufacturing composite sleepers typically involves lower energy consumption and reduces carbon footprints.

3. Excellent Mechanical Performance

* High Strength: Composite materials provide superior compressive and flexural strength, making them suitable for heavy-load railway applications.

* Elasticity: Compared to concrete sleepers, composite sleepers offer better elasticity, which helps absorb shock and reduce stress on the track system, prolonging its lifespan.

* Corrosion Resistance: Composite materials are highly resistant to water, corrosion, and UV exposure, making them ideal for harsh environments.

* Aging Resistance: The structural stability of composite sleepers ensures minimal deformation or degradation over time, with a lifespan often exceeding that of traditional sleepers.

2. Environmental Benefits

* Reduced Timber Usage: Compared to wooden sleepers, composite sleepers help conserve forest resources.

* Recyclability: Many composite sleepers are made from recycled plastics and fiberglass, and they can be recycled at the end of their service life, supporting sustainability.

* Lower Carbon Emissions: Manufacturing composite sleepers typically involves lower energy consumption and reduces carbon footprints.

3. Excellent Mechanical Performance

* High Strength: Composite materials provide superior compressive and flexural strength, making them suitable for heavy-load railway applications.

* Elasticity: Compared to concrete sleepers, composite sleepers offer better elasticity, which helps absorb shock and reduce stress on the track system, prolonging its lifespan.

![]()

Recommended Products